A NEW PARADIGM IN MODERN CONSTRUCTION

WELCOME TO NEW PARADIGM LGS

Design-Led Light Gauge Steel Building Solutions

PRE-CONSTRUCTION PLANNING

Design clarity before steel is formed.

Pre-construction planning establishes the foundation for an efficient, predictable build. Architectural, structural, and engineering data are coordinated to define scope, materials, and sequencing before manufacturing begins.

For Light Gauge Steel, this phase ensures framing components are accurately specified, waste is reduced, and fabrication transitions seamlessly from design to production -eliminating costly changes later in the process.

BIM INTEGRATION

Digital precision from design to fabrication.

Building Information Modeling (BIM) creates an intelligent 3D digital twin of the structure, integrating geometry, materials, and performance data into a single coordinated model.

For Light Gauge Steel, BIM directly drives manufacturing—generating accurate material take-offs, cut lists, and roll-forming data. This reduces errors, minimizes on-site adjustments, improves collaboration, and determines the project work scope before at the start before manufacturing begins.

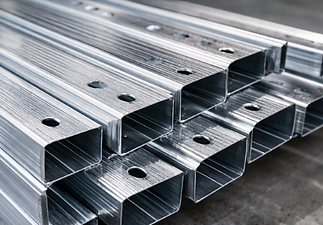

CNC ROLL FORMER MANUFACTURING

Factory-precision steel, formed to the millimeter.

Flat steel coils are transformed into structural framing components - including studs, truss, and tracks - using CNC roll-forming technology.

This autonomous cutting, punching, and shaping produce consistent, high-quality components with tight tolerances and minimal manual handling. This process enables fast production, repeatable accuracy, and scalable output for residential, commercial, DIY, and custom projects.